How Golf Clubs are Made

Golf clubs are the essential tools that allow golfers to navigate the course, execute precise shots, and express their skills and style. But have you ever wondered about the intricate process behind the creation of these remarkable instruments? In this article, we will take you on a captivating journey into the world of golf club manufacturing.

From the meticulous crafting of the club head to the selection of the perfect shaft and grip, every aspect of a golf club is carefully considered and crafted with expertise. The process combines the artistry of design, the science of materials, and the innovative technologies that drive the golf industry forward.

In this exploration, we will dive deep into the manufacturing process of golf clubs. We will unveil the secrets behind the construction of the club head, exploring the materials used and the design considerations that affect performance. We will then delve into the craftsmanship of the shaft, examining the different materials and manufacturing techniques employed to create the perfect balance of strength and flexibility.

But the story doesn’t end there. The grip, the golfer’s direct connection to the club, plays a crucial role in control and feel. We will uncover the various materials used for grips and how they are constructed to provide optimal comfort and stability.

Join us as we unravel the mysteries and intricacies of golf club manufacturing. Discover the artistry, technology, and passion that combine to create these remarkable instruments that bring joy, challenge, and excitement to golfers around the world. Prepare to be amazed by the craftsmanship and attention to detail that goes into every golf club you hold in your hands.

The Golf Club Head

The golf club head is the central component of the club, impacting distance, accuracy, and forgiveness. Let’s delve into the manufacturing process and materials used in creating golf club heads.

What is the golf club head?

The golf club head is the part of the club that makes contact with the ball. It consists of various components, including the face, sole, and cavity. Understanding the intricacies of club head design is essential to appreciate its influence on performance.

Manufacturing materials for golf club heads

Golf club heads are crafted from different materials, each with its unique characteristics. Here are some commonly used materials:

| Material | Attributes |

|---|---|

| Stainless steel | Durable, provides a solid feel, and offers forgiveness |

| Titanium | Lightweight, promotes distance, and enhances power |

| Carbon composite | Offers a combination of strength, lightness, and vibration dampening |

The choice of material depends on the specific attributes desired for a particular club model, such as forgiveness, distance, or workability.

Club Head Design and Construction

The design and construction of the golf club head greatly influence its performance. Let’s explore the considerations and techniques involved in creating club heads.

Golf club head design considerations

When designing club heads, manufacturers carefully consider factors such as playability, forgiveness, and workability. These considerations lead to two primary design types: cavity back and blade-style club heads.

Cavity back club heads

Cavity back club heads feature a hollowed-out cavity at the back, redistributing weight to the perimeter. This design provides forgiveness on off-center hits and enhances stability, making them popular among recreational and game-improvement golfers.

Blade-style club heads

Blade-style club heads have a more compact and traditional design, with a solid back and a smaller sweet spot. These club heads offer enhanced workability and precision for skilled players who prioritize shot shaping and control.

Club head manufacturing process

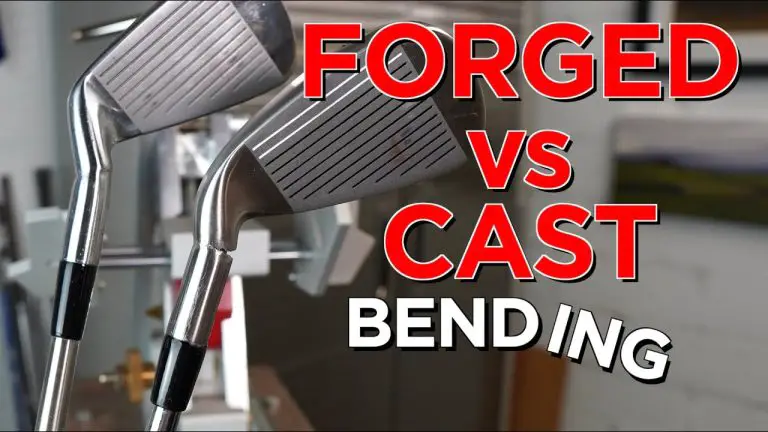

Golf club heads are typically manufactured using two primary techniques: casting and forging. Each technique has its own advantages and considerations.

Casting

Casting involves pouring molten metal into a pre-designed mold to create the club head shape. This process allows for intricate designs, precise weight distribution, and cost-effective mass production.

Forging

Forging, on the other hand, involves shaping a solid block of metal through intense heat and pressure. This technique produces a denser club head with enhanced consistency, responsiveness, and a more refined feel.

The choice between casting and forging depends on factors such as cost, desired characteristics, and target market.

Now that we have explored the manufacturing process of golf club heads, let’s move on to the next crucial component: the golf club shaft.

Golf Club Shafts

The golf club shaft plays a vital role in transmitting energy from the golfer’s swing to the club head. Understanding the materials and construction of golf club shafts is essential for optimal club performance.

What is the golf club shaft?

The golf club shaft is the long, slender component that connects the club head to the grip. It provides stability, flexibility, and torque during the swing, directly influencing the feel, trajectory, and accuracy of shots.

Shaft materials and construction

Golf club shafts are primarily made from two materials steel and graphite. Let’s delve into the characteristics of each material and the construction techniques employed.

Steel shafts

Steel shafts have been the traditional choice for golf club shafts. They offer strength, stability, and a consistent feel. Steel shafts are available in a variety of weights and flex options, catering to different swing speeds and player preferences. They are often favored by players seeking accuracy and control.

Graphite shafts

Graphite shafts have gained popularity due to their lightweight nature, which allows for increased clubhead speed and potential distance gains. They offer vibration dampening properties, resulting in a smoother feel and reduced strain on the golfer’s body. Graphite shafts are available in various flex options, making them suitable for players with different swing characteristics.

Shaft manufacturing processes and technologies

The manufacturing of golf club shafts involves advanced techniques and technologies to achieve the desired characteristics. Let’s explore some common manufacturing processes:

- Rolling: This process involves shaping a flat strip of material into a cylindrical shape, forming the foundation of the shaft.

- Wrapping: Multiple layers of graphite or steel fibers are wrapped around a mandrel to create the shaft’s structure. This process allows for precise control over stiffness, weight, and flex.

- Resin infusion: Graphite shafts often undergo a resin infusion process, where resin is injected into the wrapped layers to enhance strength, stability, and feel.

Manufacturers employ cutting-edge technology and precise engineering to ensure consistency and performance in golf club shafts.

With the golf club head and shaft covered, let’s move on to the final component: the golf club grip.

Club Grip Materials and Construction

The golf club grip is the golfer’s direct point of contact with the club. It plays a vital role in providing control, comfort, and feel during the swing. Let’s explore the materials and construction techniques used in golf club grips.

Significance of golf club grips

Golf club grips directly influence the golfer’s grip pressure, which affects swing mechanics and shot outcomes. The right grip material and construction contribute to a secure and comfortable grip, enhancing overall performance.

Types of grip materials used

Golf club grips are available in various materials, each offering different attributes and feel. Here are some commonly used grip materials:

- Rubber grips: Rubber grips provide a tacky and comfortable feel, offering excellent grip stability in different weather conditions. They are durable and widely used by golfers of all skill levels.

- Leather grips: Leather grips offer a classic and luxurious feel. They provide exceptional feedback and control, but require regular maintenance to maintain their performance and appearance.

- Synthetic materials: Synthetic grips offer a combination of durability, moisture resistance, and enhanced grip texture. They often incorporate advanced materials to provide a soft yet secure feel.

Manufacturers continually innovate to develop new grip materials that offer improved performance, longevity, and comfort.

Now that we’ve covered the components of a golf club, let’s explore how these elements are assembled and customized to cater to individual golfers.

Golf Club Assembly and Customization

The assembly process is where the golf club takes its final form, incorporating the chosen club head, shaft, and grip. Additionally, customization options allow golfers to fine-tune their clubs to match their playing style and preferences.

Putting it all together: Club assembly process

The club assembly process involves attaching the club head to the shaft and securing the grip. While this may seem straightforward, it requires precision and attention to detail to ensure optimal performance and durability.

Manufacturers use advanced adhesives, such as epoxy, to securely bond the club head and shaft. They employ specialized techniques to align the club head correctly for desired loft, lie angles, and face positions.

Customization options for golf clubs

Customization allows golfers to tailor their clubs to suit their individual preferences and playing style. Here are some common customization options:

- Club fitting: Professional club fitting involves an analysis of the golfer’s swing characteristics, including swing speed, tempo, and launch angle. This data helps determine the optimal club specifications, such as shaft flex, length, and lie angle.

- Adjustability features: Many modern golf clubs offer adjustability options, allowing golfers to fine-tune certain aspects of the club’s performance. These features may include adjustable hosels to modify loft and lie angles, or movable weights to alter the club’s center of gravity.

- Loft and lie angle customization: Golf clubs can be customized to adjust the loft and lie angles to suit a golfer’s swing and address any specific shot tendencies. This customization ensures optimal launch conditions and shot accuracy.

By leveraging customization options, golfers can optimize their equipment to maximize performance and achieve their full potential on the course.

Quality Control and Testing

To ensure that each golf club meets the highest standards of performance and quality, rigorous quality control and testing protocols are implemented throughout the manufacturing process.

Manufacturers employ a range of tests and inspections to validate the performance characteristics of golf clubs. These tests may include:

- Swing weight and balance testing: Golf clubs are evaluated to ensure proper weight distribution, swing weight, and overall balance. This testing ensures that the club feels comfortable and promotes a smooth, controlled swing.

- Performance testing and validation: Golf clubs undergo extensive testing to assess key performance parameters such as ball speed, launch angle, spin rates, and forgiveness. These tests help validate the design and engineering of the clubs, ensuring they deliver the desired performance attributes.

By subjecting golf clubs to stringent quality control and testing, manufacturers ensure that each club performs consistently and meets the expectations of golfers of all skill levels.

Innovations and Technological Advancements

The golf industry is characterized by continuous innovation and technological advancements. Let’s explore some recent innovations that have shaped the manufacturing of golf clubs.

Recent advancements in golf club manufacturing

- Adjustable hosels and weight systems: Manufacturers have introduced advanced hosel designs that allow golfers to modify loft, lie angle, and face angle settings. Similarly, weight systems provide the ability to adjust the club’s center of gravity, optimizing launch conditions and shot shape.

- Impact of computer-aided design (CAD) and 3D printing: CAD software and 3D printing technology have revolutionized the design and prototyping stages of golf club manufacturing. These advancements enable precise engineering and rapid iteration, resulting in more sophisticated club designs and faster development cycles.

Future Trends in Golf Club Manufacturing

The future of golf club manufacturing holds exciting possibilities. Here are some emerging trends to watch for:

- Integration of sensors and data analysis: Golf clubs equipped with sensors can capture data during swings, providing valuable insights into swing mechanics, club dynamics, and shot performance. This data analysis can help golfers make informed equipment choices and improve their game.

- Advancements in materials and manufacturing processes: Ongoing research focuses on developing new materials and manufacturing techniques to further enhance club performance. This includes the exploration of lightweight yet strong materials, advanced carbon fiber composites, and innovative manufacturing methods to optimize performance attributes.

As technology continues to advance, golf club manufacturers are poised to push the boundaries of innovation, delivering clubs that offer improved performance, feel, and customization options.

Conclusion

The manufacturing process of golf clubs combines artistry, engineering, and cutting-edge technology to create equipment that enhances a golfer’s performance on the course. From the carefully designed club heads to the precisely crafted shafts and grips, each component undergoes meticulous attention to detail to ensure optimal performance.

The golf club head, constructed from materials such as stainless steel, titanium, or carbon composite, undergoes casting or forging techniques to shape its design. The choice of club head design, whether cavity back or blade-style, influences forgiveness, playability, and workability.

Golf club shafts, made of steel or graphite, play a crucial role in transmitting energy from the golfer’s swing to the club head. Manufacturing processes like rolling, wrapping, and resin infusion are employed to create shafts with specific flex characteristics and weight distribution.

The golf club grip, available in materials such as rubber, leather, or synthetic compounds, provides the golfer with a secure and comfortable hold. The grip’s material and construction influence grip stability, feel, and durability.

The assembly process brings together the club head, shaft, and grip. Expert craftsmanship is required to ensure a secure and proper bond between the components. Customization options, including club fitting and adjustability features, allow golfers to tailor their clubs to their unique swing characteristics and preferences.

Throughout the manufacturing process, strict quality control measures are in place to ensure that each club meets performance standards. Swing weight and balance testing, as well as performance evaluations, help validate the club’s design and engineering.

Recent innovations in golf club manufacturing have introduced adjustable hosels, weight systems, and the integration of computer-aided design (CAD) and 3D printing. Future trends indicate the integration of sensors and data analysis, as well as advancements in materials and manufacturing processes.

In conclusion, the intricate process of manufacturing golf clubs combines art, science, and technology to produce equipment that meets the demands of golfers at all skill levels. From the carefully designed club heads to the precisely constructed shafts and grips, each component is crafted with precision and care. By understanding the manufacturing process behind golf clubs, golfers can gain a deeper appreciation for the craftsmanship that goes into creating these essential tools of the game.